Heat staking is one of the many processes used in plastic assembly when at least one of the parts is made from thermoplastic.

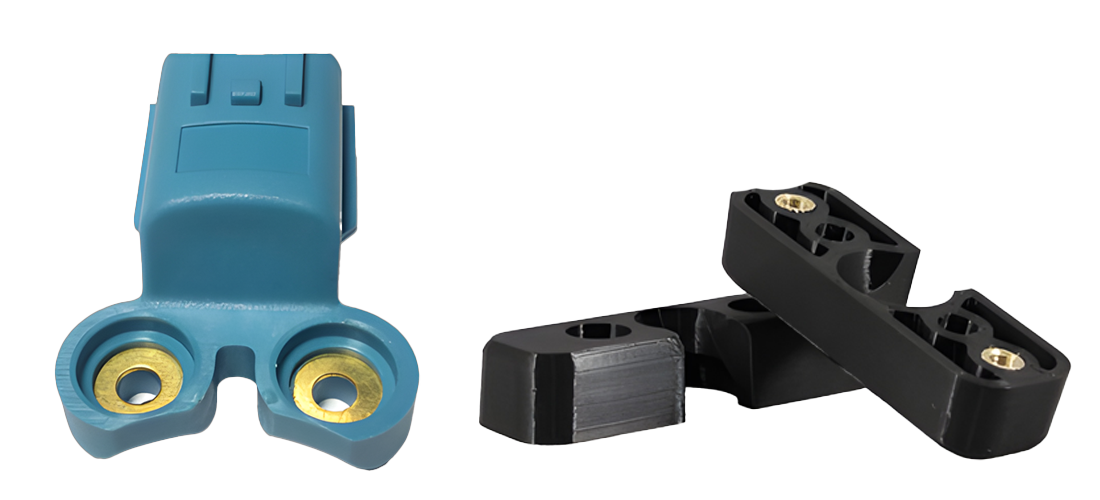

In most cases, heat staking is the preferred method for joining metal parts to plastics. It is also used to join two dissimilar plastic components.

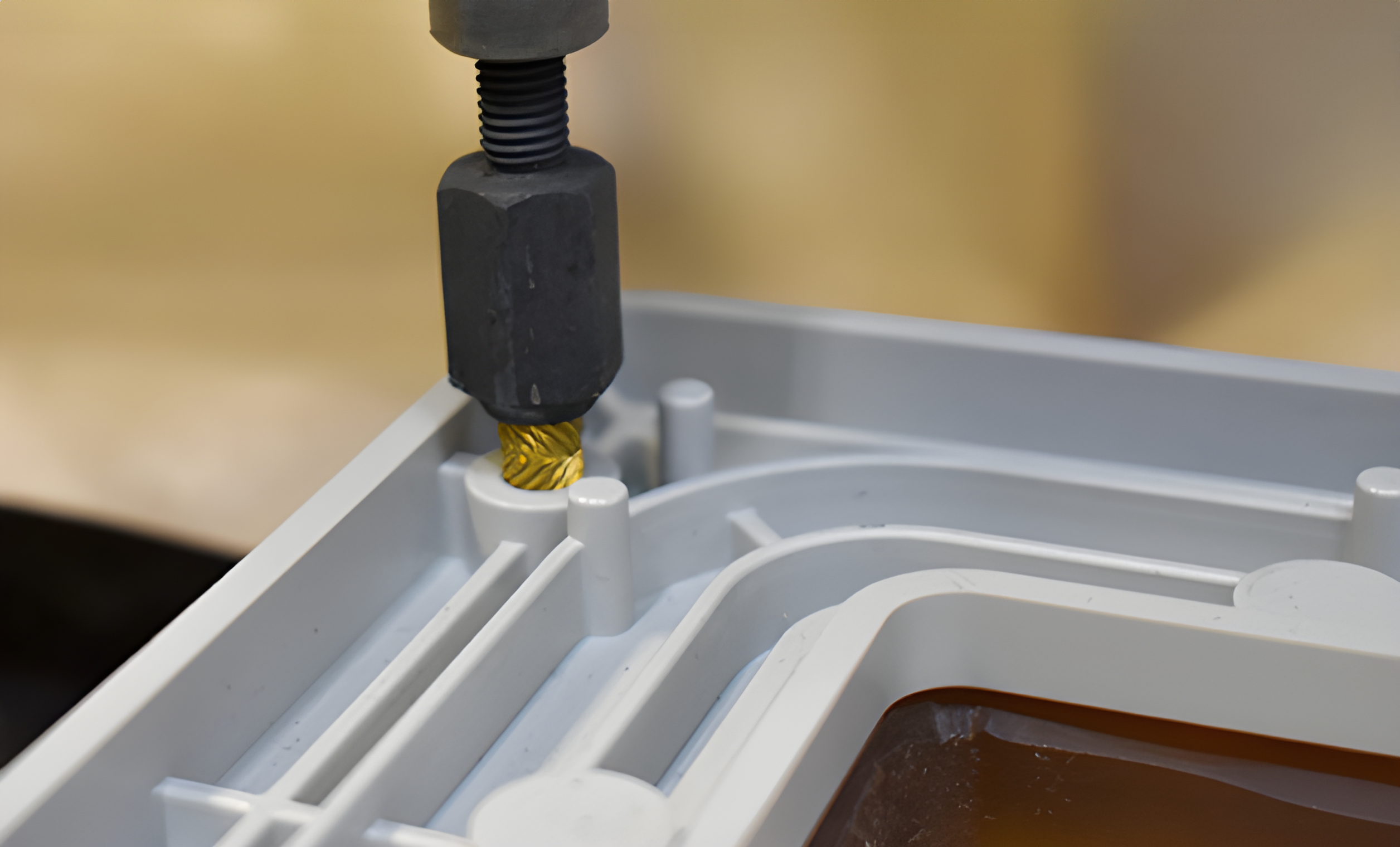

Heat staking process combines the use of heat and pressure, to soften a specific area of the plastic enough to be remolded into a new shape or profile that forms over or around the connecting part. Once cooled, it is the plastic’s strength that holds the mating part in place.

With heat staking, you have a permanent assembly without the use of other fasteners or hardware.

Heat staking can also be used to add metal inserts to aid in multi-part assemblies.

Heat staking has been found to be a very effective, controllable and repeatable process.

Because heat staking is performed after a part is molded, part assembly considerations need to be taken during product development.

Part components need to be designed for the type of assembly that will be used. For heat staking, the plastic part will usually have a boss which is a feature that is raised above the surface.

The mating part will have holes that are sized and strategically placed to meet up with the boss during assembly. The bosses will fit into the holes and will allow for heat staking to occur.

There are other fastener-based technologies to hold parts together, but there are many advantages to the heat staking process including:

- All heat staking can occur in one machine cycle, whereas other methods have multiple steps for each location on the part, such as installing multiple threaded inserts.

- No vibration damage or stress cracks to sensitive electronic components due to precise, localized application.

- No particulates from other materials used.

- Ability to stake metalized coated applications.

- Ability to reach difficult to access areas.

- Eliminates the need for extra hardware, which can become defective, break, or otherwise suffer from quality control issues.

- Less costly and less labor intensive to other hardware fastening options