Optosem emphasize excellent quality tooling produce good parts. Injection molding tooling design is a critical aspect of the injection molding process, which involves creating molds used to produce plastic parts in high volumes. The design of the tooling directly impacts the quality, efficiency, and cost-effectiveness of the production process.

Key elements involved in injection molding tooling design as per below:

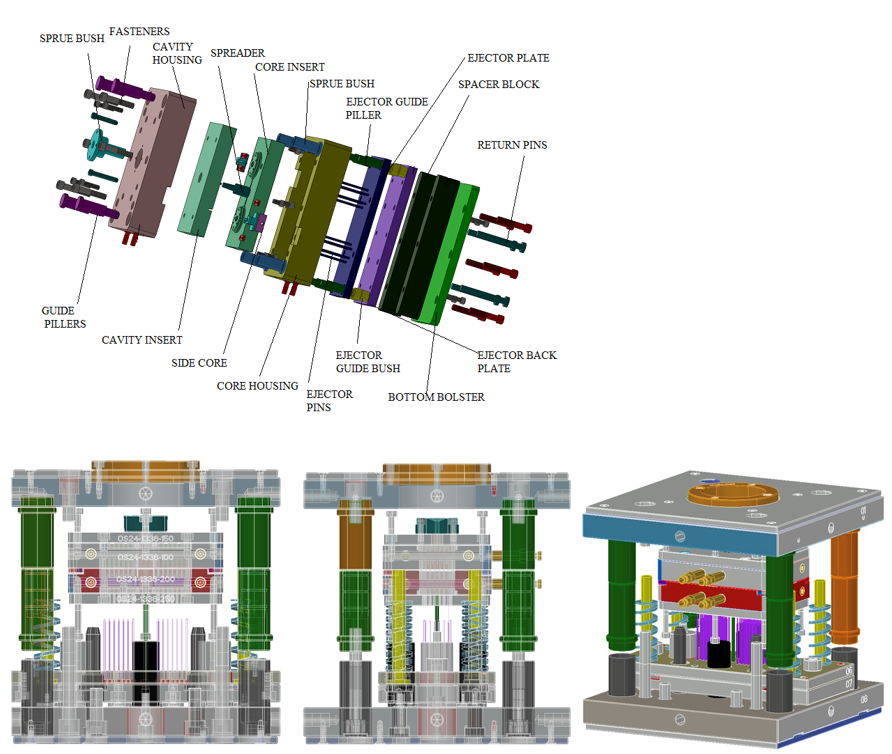

- Tooling Components which included Mold Base, Cavities and Cores, Sprue, Runners, Gates and Cooling Channel.

- Design Considerations involved Material Selection, Tolerance, Ejection System and Ventilation.

- Types of Molds such as Single Cavity Molds, Multi Cavity Molds and Family Molds.

- Advanced Tooling Techniques like selection of Hot Runner Systems.

- Design Process which included Concept and Feasibility review that normally with 3D Modeling.

- Quality Control and Mold Maintenance planning.

Injection molding tooling design is a complex, multidisciplinary process that requires careful consideration of material properties, manufacturing techniques, and design principles to produce high-quality plastic parts efficiently.