Horizontal HPM

Ideal for large-scale production with high speed, automation, and smooth material flow.

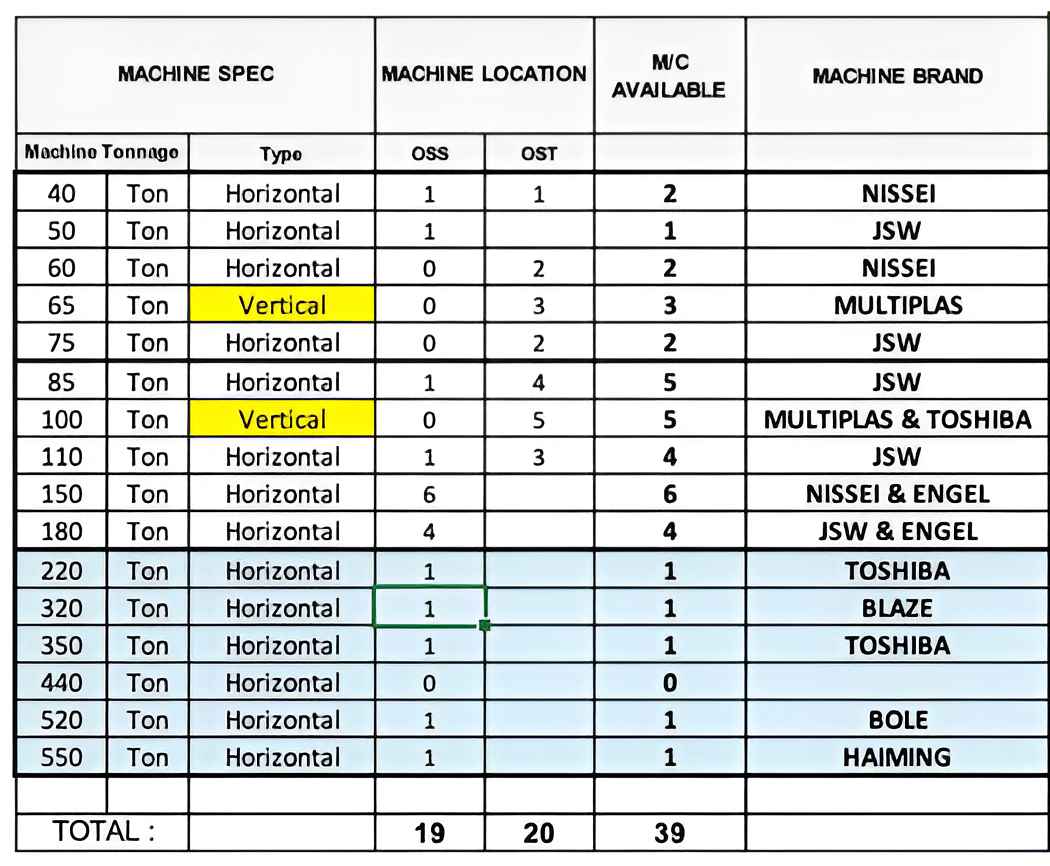

At Optosem, we operate 40 advanced injection molding machines, both horizontal and vertical, ranging from 40 to 550 tons. Our fleet includes hydraulic and electric machines sourced from top European and Japanese brands, renowned for their high precision and reliability.

Our diverse machinery allows us to meet a wide range of customer needs, from high-volume production to smaller, specialized batches, as part of our comprehensive turnkey solutions.

Optosem utilizes two types of injection molding machines: Horizontal and Vertical. Each type offers unique advantages tailored to specific applications. The selection between horizontal and vertical machines depends on various production requirements, such as part size, production volume, and the need for insert or multi-component molding.

For reference, the table below highlights 20 machines dedicated to Optosem Solutions.

Below is the advantages of Vertical Injection Machine.

Ideal for large-scale production with high speed, automation, and smooth material flow.

Ideal for insert molding, multi-component production, and factories with limited space.

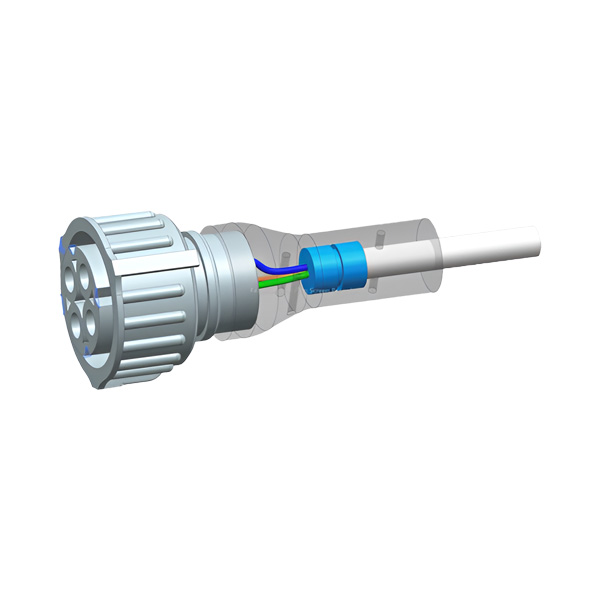

Low-pressure molding provides cost-effective sealing and protection for diverse electronic components.

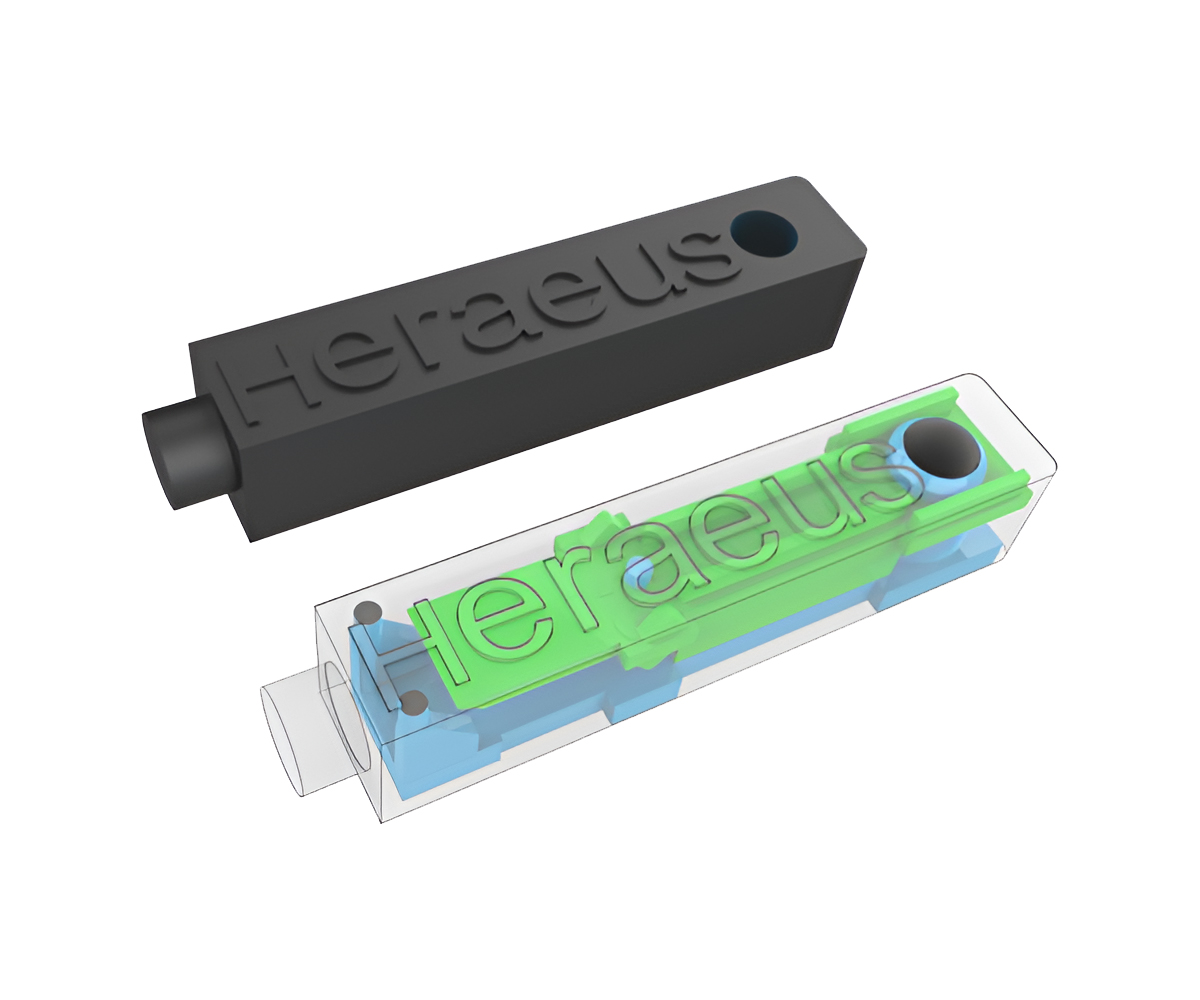

Over molding creates strong, bonded parts with faster production and customization options.

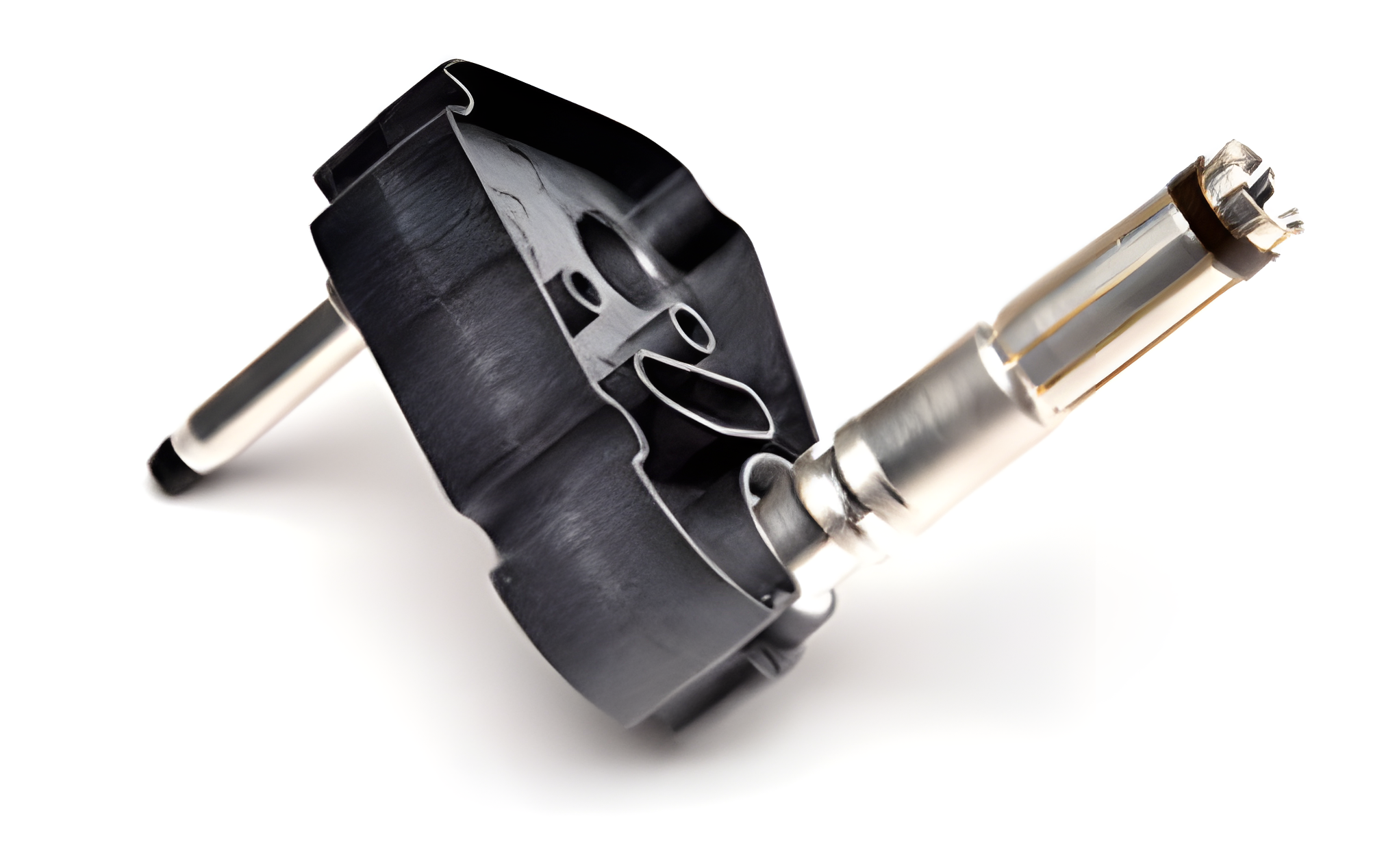

Insert molding seamlessly integrates metals and plastics, enhancing strength, durability, and weight reduction.