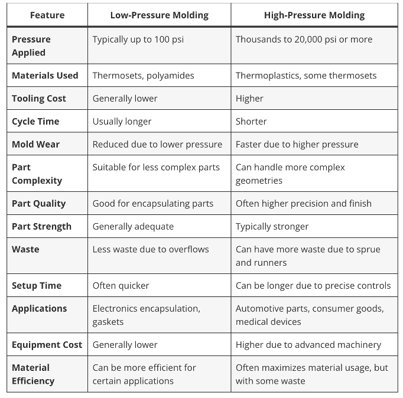

Low-pressure molding is a crucial innovation with various applications across various industries. This versatile technology offers a cost-effective and efficient solution for sealing, protecting, and encapsulating electronic components, cables, and more.

Low pressure molding materials are specially designed for PCB protection while helping you cut cost and improve quality across different applications.

Low pressure molding is a faster and more efficient process than conventional potting.

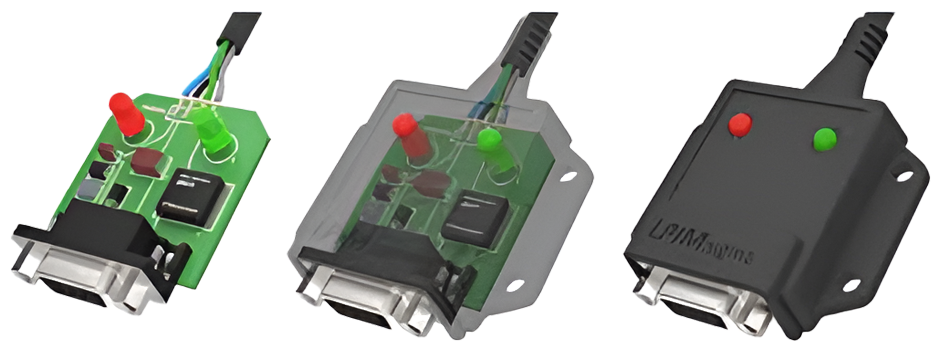

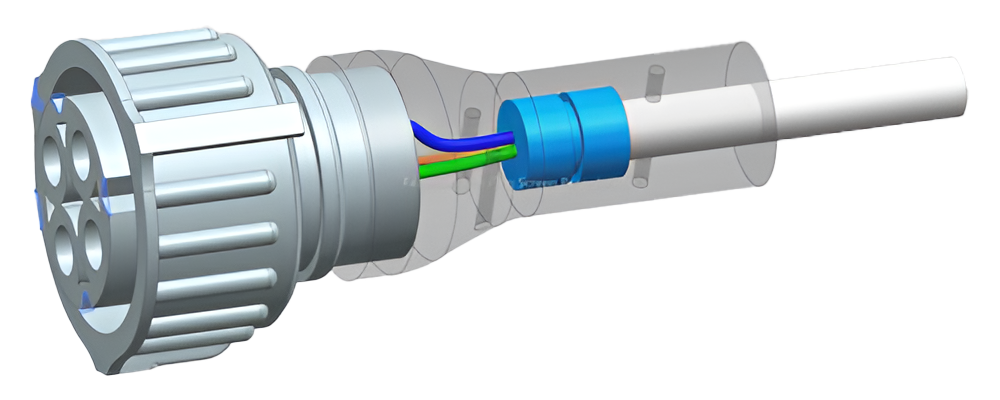

Low-pressure molding is a versatile and customizable process, ideal for a wide range of applications such as circuit boards, LEDs, LCDs, batteries, cables, and more. Its flexibility allows manufacturers to create molds in nearly any shape or size, enabling the design of durable and visually appealing protective enclosures for electronic components.

This method offers effective protection for sensitive electronics by providing robust sealing and insulation, making it suitable for applications requiring precision and reliability.